OUR DOOR IS ALWAYS OPEN

To find out more call us on 0330 058 0988 or email us at info@safehingeprimera.com

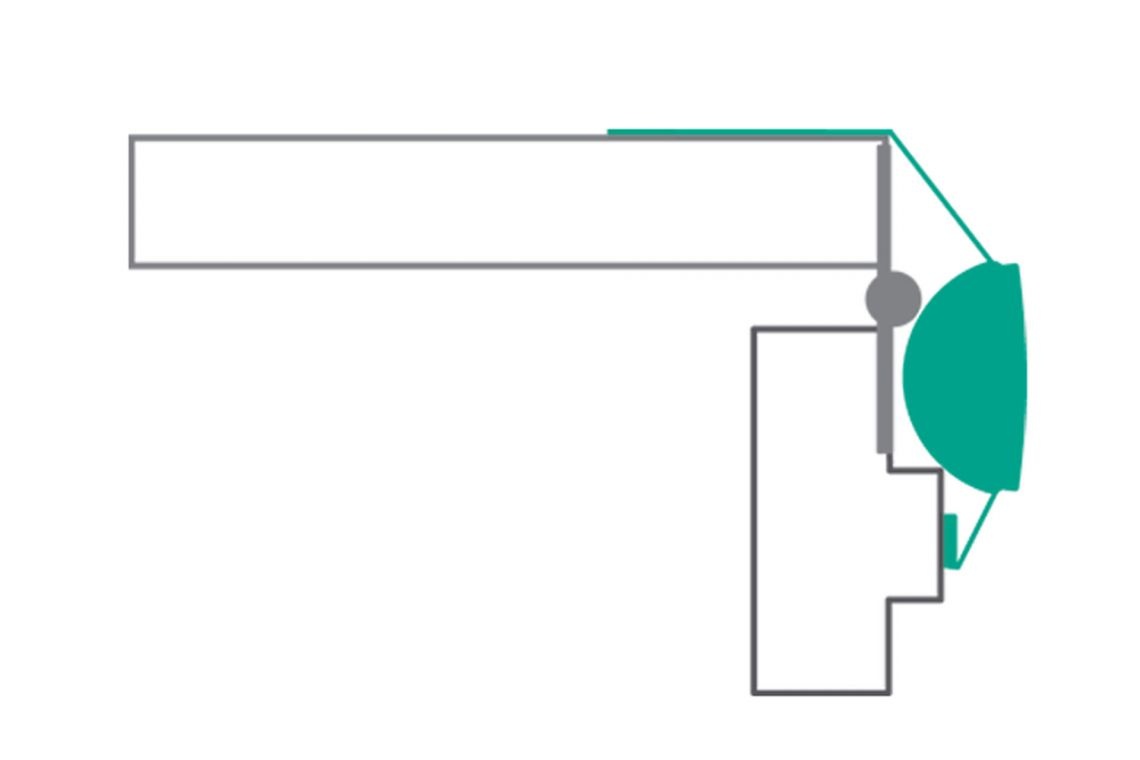

Perfect for existing hinged doors, our surface-mounted finger-ejecting guard offers a maximum opening angle of 180° and has a patented finger-ejection system to keep wandering fingers safe.

The unique design sees the semi-circular aluminium body floating on two retracting fabric sections. When the door opens, it moves into the gap and the tear-resistant fabric covers any remaining gaps — as well as ejecting any fingers that may stray inside.

It’s this clever semi-circular geometry – rather than fabric tension – that keeps fingers safe and uses extremely low force springs to maintain the door’s original opening force. Its tough aluminium build can also withstand knocks and bumps and wipes clean easily.

To find out more call us on 0330 058 0988 or email us at info@safehingeprimera.com

As the door opens, the aluminium body floats into the gap and the taut fabric covers any other gaps. The fabric’s patented finger ejection system makes it almost impossible to trap a finger.

Unlike roller blind finger guards, which use fabric tension to keep fingers out, Alumini’s fabric has nominal impact on the opening resistance. So your doors will still comply with Approved Document M and BS 8300.

The durable aluminium body floats into the hinge reveal gap, with tear-resistant fabric covering any remaining gaps.

As the door closes, the fabric retracts – ejecting fingers.

Alumini’s clever design allows unrestricted door opening up to 180°, making it ideal for wheelchairs and trolleys or for gym hall doors where you can’t use floor mounted stops.

The aluminium profile floats into the hinge reveal gap when the door is open at 100°, so it doesn’t block the doorway. This allows a maximum clear opening width that’s ideal for wheelchairs and trolleys.

With our finger-ejecting guard, you can still enjoy a safe and durable solution within budget. It’s hard wearing and can save over £300 compared to plastic finger guards.

Unlike traditional rubber and roller blind finger guards, Alumini’s polyurethane-backed fabric is easy to clean and tear-resistant, reducing the risk of vandalism.

The hard-wearing aluminium profile is also designed to withstand any knocks in a high traffic environment.

Unlike roller blind finger guards, which use fabric tension to keep fingers out, Alumini’s fabric has nominal impact on the opening resistance. So your doors will still comply with Approved Document M and BS 8300.

The durable aluminium body floats into the hinge reveal gap, with tear-resistant fabric covering any remaining gaps.

As the door closes, the fabric retracts – ejecting fingers.

The aluminium profile floats into the hinge reveal gap when the door is open at 100°, so it doesn’t block the doorway. This allows a maximum clear opening width that’s ideal for wheelchairs and trolleys.

Unlike traditional rubber and roller blind finger guards, Alumini’s polyurethane-backed fabric is easy to clean and tear-resistant, reducing the risk of vandalism.

The hard-wearing aluminium profile is also designed to withstand any knocks in a high traffic environment.

You can change your preferences or unsubscribe at any time. You agree to Safehinge Primera using your personal data in accordance with our privacy policy. We use your data to personalise and improve your experience on our digital platforms, provide products and services you request from us, and carry out market research. We will never sell your personal data to third parties.

You can change your preferences or unsubscribe at any time. You agree to Safehinge Primera using your personal data in accordance with our privacy policy. We use your data to personalise and improve your experience on our digital platforms, provide products and services you request from us, and carry out research. We will never sell your personal data to third parties.

Alumini rear is our hinge-knuckle guard that protects fingers on the 'pull' side of the door. To do this, it fills the small yet dangerous gap created by standard hinged doors, replicating its shape and size for the full length with completely static protection.

If the door opens right back to 180°, eg it's in the middle of a wall, then the hinge knuckle guard is strongly recommended.

Alumini rear comes in a standard length which is cut to size and fitted in just 10 minutes.

As the first attempt at finger safety, plastic guards covered the gap between the door and frame. In some situations, like the home, they’re safe and do the job. However, in high traffic areas, like schools, hospitals, restaurants and retail environments, they’re simply not durable enough.

They crack and split

Although cheap, plastic finger guards aren’t built to last. Typically, after between six months and two years of normal use in schools, GPs, restaurants or swimming pools, they split and need replacing. And once broken, the original danger is exposed, putting fingers at risk.

A maintenance liability

The real cost of a plastic finger guard is anything but cheap. Taken over the typical 25-year lifespan of a school, replacing them costs between £500 and £1,000 per door, making them the most expensive option.

Look cheap

Plastic guards can be unsightly and rarely blend in with the environment. If the interior finish and doors have been carefully planned – perhaps in colourful laminate or attractive veneer – the finger guard should be just as aesthetically pleasing.

The single roller blind uses fabric tension to resist fingers pushing into the gap. And when you consider the cost of hinges, the roller blind finger guard, and the fitting, the cost is similar to our integral finger guard – which designs out the problem, offering superior safety and aesthetics.

Just hides gap

Unlike our clever designs, roller blind finger guards use fabric tension to create resistance and prevent trapped fingers. This is mostly effective but it’s not foolproof.

Affects opening force

The fabric tension resistance can make it challenging to comply with Approved Document M and BS 8300 (Opening Force for a Door).

A costly compromise

Roller blinds cost around the same as our Alumax integral finger guard — yet compromise on aesthetics. And if cost is an issue, our retrofit finger guard makes the perfect alternative. It’s durable and doesn’t impact the opening force.

Flexible rubber hinge covers were developed to address the durability issues of plastic finger guards. Hard wearing and tough, they cover the complete gap, however fingers can still become trapped.

Doesn’t solve the problem

Rubber guards merely cover the gap between the door and frame. The rubber cover is rarely taut enough to prevent the guard being pushed into the hinge gap. This leaves open the possibility of fingers wandering into the gap and being trapped in a closing door.

Highly visible

Concertina-like rubber hinge covers are made from a material not usually used on doors. Even in the closed position, customers comment they’re eyecatching and impact the overall aesthetic.

Gathers dust and grime

The soft rubber surface attracts dust and is hard to clean. The folds also gather grime, which can become a hiding place for bacteria.

UK - Glasgow

44 Speirs Wharf

Glasgow

G4 9TH

t: +44 330 058 0988

e: info@safehingeprimera.com

UK - Blackpool

Unit 8 Bankfield House

250 Bristol Avenue

Blackpool

FY2 0JF

t: +44 330 058 0988

e: sales@safehingeprimera.com

USA - Boston MA

177 Huntington Ave

17th Floor

Boston

MA. 02115

t: +1 347. 506. 2114

e: inquiries@safehingeprimera.com

AU - Hipac Head Office

36 Long Street

Goulburn

New South Wales

Australia 2580

UK - Glasgow

44 Speirs Wharf

Glasgow

G4 9TH

t: +44 330 058 0988

e: info@safehingeprimera.com

UK - Blackpool

Unit 8 Bankfield House

250 Bristol Avenue

Blackpool

FY2 0JF

t: +44 330 058 0988

e: sales@safehingeprimera.com

USA - Boston MA

177 Huntington Ave

17th Floor

Boston

MA. 02115

t: +1 347. 378. 0174

e: inquiries@safehingeprimera.com

© Safehinge Primera 2023. Design By Submarine. Development By Crocodiles